AVOID COMMON MISTAKES with

Performance Camshaft

Replacement

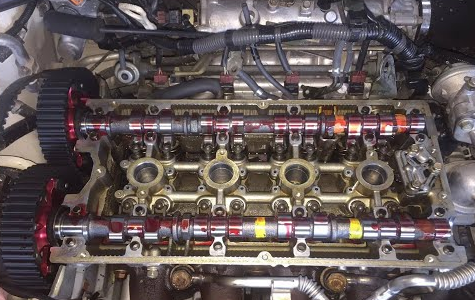

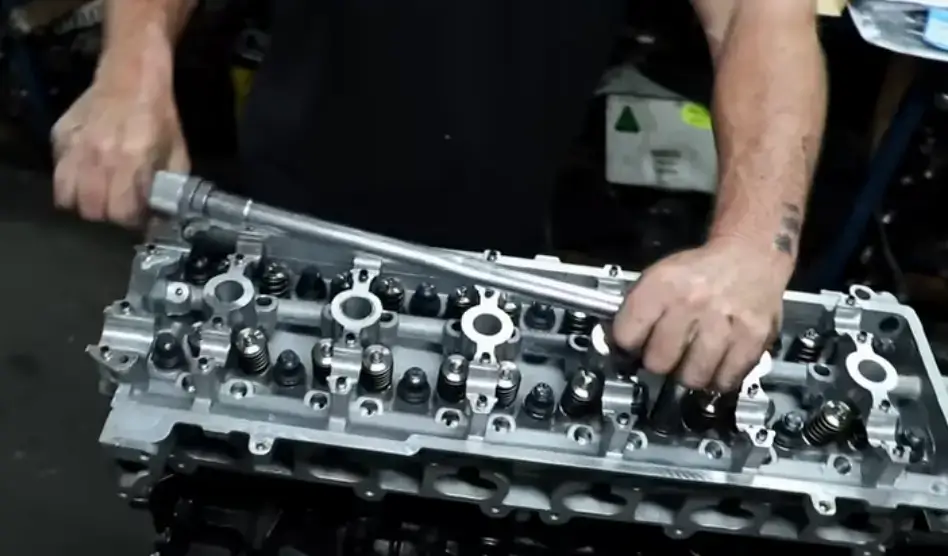

Remember, it's crucial to clean every part thoroughly before installing it in an engine. Never assume that the parts come already cleaned before packaging. Always check cam bolts, spring retainers, springs for any damage & wear and tear

Thomas

Research & Development

The camshaft usually isn't the culprit for failure. Rather, the so-called camshaft failure tends to stem from one of these four issues.