Inside the World of Vehicle Camshaft Manufacturing

Step inside the intricate world of vehicle camshaft manufacturing, where precision and artistry converge to shape the heart of automotive performance. With cutting-edge technology and painstaking craftsmanship, these essential components are brought to life, setting the stage for unparalleled engine efficiency and power delivery. From the raw materials to the final polished product, every step in the manufacturing process showcases the fusion of engineering expertise and precision engineering.

Vehicle Camshafts

Camshafts are integral components of internal combustion engines, responsible for controlling the opening and closing of the engine's intake and exhaust valves. As the camshaft rotates, its lobes push against the valves, allowing the intake of air and fuel and the expulsion of exhaust gases. This synchronized process is crucial for optimizing engine performance, fuel efficiency, and emissions control. Without precisely engineered camshafts, the smooth and efficient operation of an engine would be compromised.

The design and functionality of camshafts directly impact an engine's power delivery, torque characteristics, and overall responsiveness. Whether in high-performance sports cars or everyday commuter vehicles, the camshaft's influence on engine behavior is undeniable. With the demand for greater efficiency and performance, the art of camshaft manufacturing continues to evolve, driving advancements that elevate the driving experience for professional automotive racing drivers, car enthusiasts to everyday drivers alike.

The Precision Engineering Behind Camshaft Manufacturing

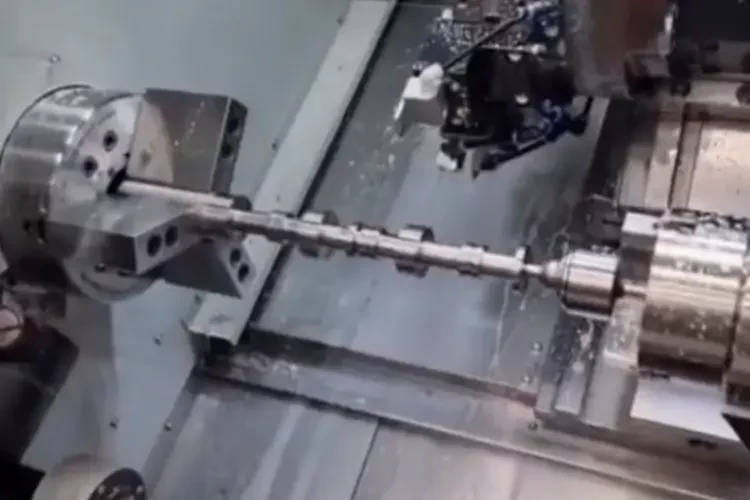

The manufacturing of a vehicle camshaft demands an unparalleled level of precision engineering, where the slightest deviation can have significant effects on engine performance. Modern camshaft production involves advanced machinery, computer-aided design (CAD), and sophisticated manufacturing techniques that ensure the highest degree of accuracy and consistency. From concept to execution, every stage of the process is meticulously planned and executed to meet stringent quality standards.

Crafting camshafts begins with the selection of high-quality materials, such as alloy steels or ductile iron, known for their durability, strength, and heat resistance. These raw materials undergo rigorous testing and analysis to ensure they meet the exact specifications required for camshaft production. Once verified, the materials are precision-machined to create the intricate profiles and contours that define the camshaft's lobes, ensuring precise valve timing and lift throughout the engine's operating range.

The camshaft's journals, which rotate within the engine block, undergo meticulous grinding and finishing processes to achieve the precise dimensions and surface smoothness necessary for optimal performance and longevity. This level of precision engineering is a testament to the dedication and expertise required to produce camshafts that meet the demanding requirements of modern engines.

The manufacturing process of vehicle camshafts is a multifaceted journey that blends precision machining, heat treatment, and meticulous quality control. It begins with the creation of a detailed design, often utilizing computer-aided design (CAD) software to model the camshaft's profiles, lobes, and journals. This digital blueprint serves as the foundation for the subsequent manufacturing steps, guiding the production team through each stage of the process.

Once the design is finalized, the raw materials undergo precision machining to transform them into rough camshaft blanks, closely resembling the final shape of the component. This machining phase demands the utmost precision to achieve the intricate contours and profiles that define the camshaft's functionality. Subsequent heat treatment processes, such as induction hardening or nitriding, are employed to enhance the surface hardness and wear resistance of the camshaft, ensuring it can withstand the rigors of engine operation.

Following heat treatment, the camshaft undergoes precision grinding to achieve the exacting tolerances and surface finish required for optimal performance. This stage involves advanced grinding machinery and meticulous quality control measures to verify that each camshaft meets the specified dimensional and geometric criteria. The final finishing touches, including polishing and surface treatments, elevate the camshaft to its ultimate form, ready to unleash the precision and power within a vehicle's engine.

The pursuit of precision in camshaft manufacturing is underpinned by rigorous quality control and inspection processes that safeguard the integrity and performance of the final product. At every stage of production, from material selection to final finishing, stringent quality standards and inspection protocols are employed to identify any deviations or imperfections that could compromise the camshaft's functionality.

Advanced metrology equipment, such as coordinate measuring machines (CMM) and optical inspection systems, enable manufacturers to assess the dimensional accuracy, surface finish, and profile consistency of each camshaft. These precision instruments provide detailed measurements and visual analyses, allowing for meticulous scrutiny of the camshaft's critical features. Additionally, non-destructive testing methods, including magnetic particle inspection and ultrasonic testing, are utilized to detect any internal defects or irregularities that could impact the camshaft's structural integrity.

Furthermore, comprehensive performance testing, such as dynamic valve train simulations and endurance trials, validates the camshaft's functionality under real-world operating conditions. This comprehensive approach to quality control ensures that every camshaft that leaves the manufacturing facility meets the exacting standards required for superior engine performance, reliability, and longevity.

The realm of camshaft technology continues to evolve, driven by relentless innovation and a commitment to unlocking new levels of engine performance and efficiency. Advancements in materials science, manufacturing techniques, and digital design tools have revolutionized the way camshafts are developed, resulting in components that are lighter, stronger, and more precisely engineered than ever before.

One notable innovation is the integration of hollow camshaft designs, which reduce weight and inertia while maintaining structural integrity and performance. By strategically removing material from within the camshaft, manufacturers can achieve significant weight reductions without compromising the component's strength or durability. This approach contributes to overall engine efficiency and responsiveness, particularly in high-speed and high-revving applications where reduced mass is advantageous.

Furthermore, the application of advanced surface treatments, such as diamond-like carbon (DLC) coatings and ion nitriding, enhances the wear resistance and friction characteristics of camshafts, promoting longevity and reducing parasitic losses within the engine. These surface treatments create a robust barrier against wear and ensure smooth operation, contributing to improved fuel efficiency and reduced emissions over the lifespan of the camshaft.

Additionally, the utilization of additive manufacturing, or 3D printing, has opened new frontiers in camshaft design and production. This cutting-edge technology allows for the creation of complex internal geometries and optimized structures that were previously unattainable through traditional manufacturing methods. The result is a new generation of lightweight, precisely tailored camshafts that push the boundaries of performance and efficiency in automotive engines.

The design of a camshaft exerts a profound influence on an engine's performance characteristics, shaping its power delivery, torque curve, and overall drivability. The intricacies of camshaft design, including lobe profile, duration, and lift, directly dictate how an engine breathes, combusts fuel, and expels exhaust gases. As a result, the selection and optimization of camshaft parameters are pivotal in tailoring an engine's behavior to meet specific performance objectives.

High-performance camshafts are engineered to maximize airflow, optimize valve timing, and enhance combustion efficiency, all of which contribute to increased horsepower and torque output. Aggressive camshaft profiles, characterized by high lift and extended duration, promote robust power delivery at higher engine speeds, ideal for applications where top-end performance is paramount. Conversely, milder camshaft designs prioritize low-end torque and drivability, catering to everyday driving scenarios where responsiveness and flexibility are valued.

Camshaft design also plays a crucial role in achieving emissions compliance and fuel efficiency targets. By carefully controlling valve timing and overlap, engineers can minimize exhaust emissions and improve fuel economy without sacrificing performance. This balance between power output, emissions control, and efficiency underscores the pivotal role of camshaft design in shaping the holistic performance of modern engines.

The design of a camshaft exerts a profound influence on an engine's performance characteristics, shaping its power delivery, torque curve, and overall drivability. The intricacies of camshaft design, including lobe profile, duration, and lift, directly dictate how an engine breathes, combusts fuel, and expels exhaust gases. As a result, the selection and optimization of camshaft parameters are pivotal in tailoring an engine's behavior to meet specific performance objectives.

High-performance camshafts are engineered to maximize airflow, optimize valve timing, and enhance combustion efficiency, all of which contribute to increased horsepower and torque output. Aggressive camshaft profiles, characterized by high lift and extended duration, promote robust power delivery at higher engine speeds, ideal for applications where top-end performance is paramount. Conversely, milder camshaft designs prioritize low-end torque and drivability, catering to everyday driving scenarios where responsiveness and flexibility are valued.

Camshaft design also plays a crucial role in achieving emissions compliance and fuel efficiency targets. By carefully controlling valve timing and overlap, engineers can minimize exhaust emissions and improve fuel economy without sacrificing performance. This balance between power output, emissions control, and efficiency underscores the pivotal role of camshaft design in shaping the holistic performance of modern engines.

The pursuit of maximum performance often leads to the customization and optimization of camshafts for high-performance vehicles. Kelford Cams expertise to develop bespoke camshaft profiles that extract the utmost potential from an engine without compromising reliability or drivability. This tailored approach to camshaft design enables Engine Builders, enthusiasts and professional racers to fine-tune their engine's behavior to suit specific racing disciplines or driving preferences.

Custom camshaft profiles are meticulously engineered to align with an engine's specific attributes, such as compression ratio, cylinder head airflow, and exhaust system dynamics. By optimizing the camshaft's lift, duration, and lobe separation angles, engineers can unleash additional horsepower and torque while preserving the engine's durability and tractability. This bespoke tuning process often involves extensive dynamometer testing and real-world evaluations to validate the camshaft's performance across a broad range of operating conditions.

In addition to custom profiles, high-performance camshafts may feature advanced materials, such as billet steel or aerospace-grade alloys, to withstand the elevated stresses and temperatures encountered in racing environments. These specialized materials, combined with cutting edge technology and precision CNC manufacturing techniques, ensure that custom camshafts deliver uncompromising performance and reliability, meeting the exacting demands of competitive motorsport and enthusiast-driven applications.

As the automotive industry embraces electrification, hybridization, and advanced powertrain technologies, the future of vehicle camshaft manufacturing is poised for further evolution. While traditional internal combustion engines will continue to benefit from innovative camshaft designs and materials, the rise of electrified propulsion systems presents new opportunities for innovative camshaft applications.

In hybrid and electric powertrains, camshaft technology may play a role in optimizing valve timing for internal combustion generators or range-extending engines, where precise control of valve events remains crucial for efficiency and emissions management. Furthermore, as manufacturers explore new forms of combustion and energy conversion, camshaft designs tailored for unconventional engine configurations, such as opposed-piston layouts or free-piston generators, may emerge to support next-generation powerplant architectures.

Moreover, the integration of advanced sensors, actuators, and digital control systems into camshaft assemblies could enable real-time adjustments to valve timing and lift, maximizing the efficiency and responsiveness of internal combustion engines in hybrid applications. These smart camshaft technologies hold the potential to enhance the overall performance and environmental impact of future hybrid vehicles, aligning with the industry's pursuit of sustainable mobility solutions.

Beyond electrification, the ongoing quest for lightweight and durable materials, as well as the continual refinement of manufacturing processes, will drive the next wave of innovation in camshaft production. From advanced surface coatings to nano-engineered materials, the future of vehicle camshaft manufacturing promises to deliver components that elevate engine performance, efficiency, and sustainability in the ever-evolving automotive landscape.

The art of high performance vehicle camshaft manufacturing embodies the synergy of engineering excellence and artistic mastery, shaping the heartbeat of automotive performance. From the meticulous selection of materials to the advanced manufacturing processes and innovative design techniques, every facet of camshaft production showcases the unwavering dedication to achieving unparalleled precision and functionality.

As the automotive industry continues to push the boundaries of performance, efficiency, and sustainability, the role of camshafts remains pivotal in shaping the driving experience. With a legacy of precision engineering and a future defined by innovation, vehicle camshaft manufacturing stands as a testament to the enduring pursuit of excellence in the art and science of automotive propulsion.

Step inside the world of vehicle camshaft manufacturing, where precision meets artistry, and witness the intricate dance of technology and craftsmanship that propels the vehicles we admire and rely on every day. Embrace the precision. Embrace the art. Embrace the future of automotive performance.

Avoid camshaft damage and installation mistakes! Our team has prepared a concise article to help you avoid common errors. We strive to deliver up-to-date information. Coming April 20th.